MOSS VRS®+ obelisc®

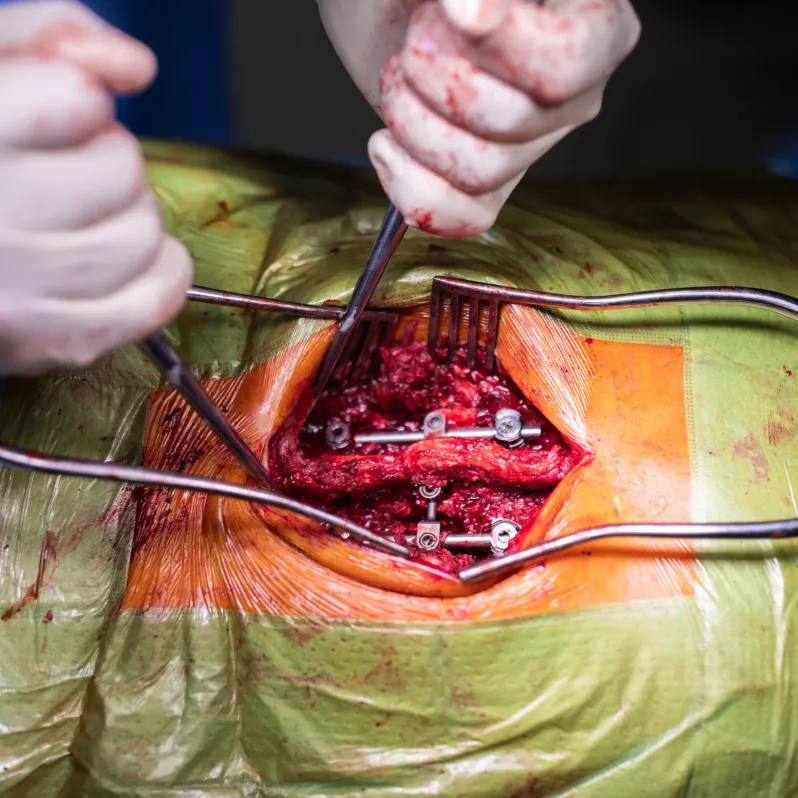

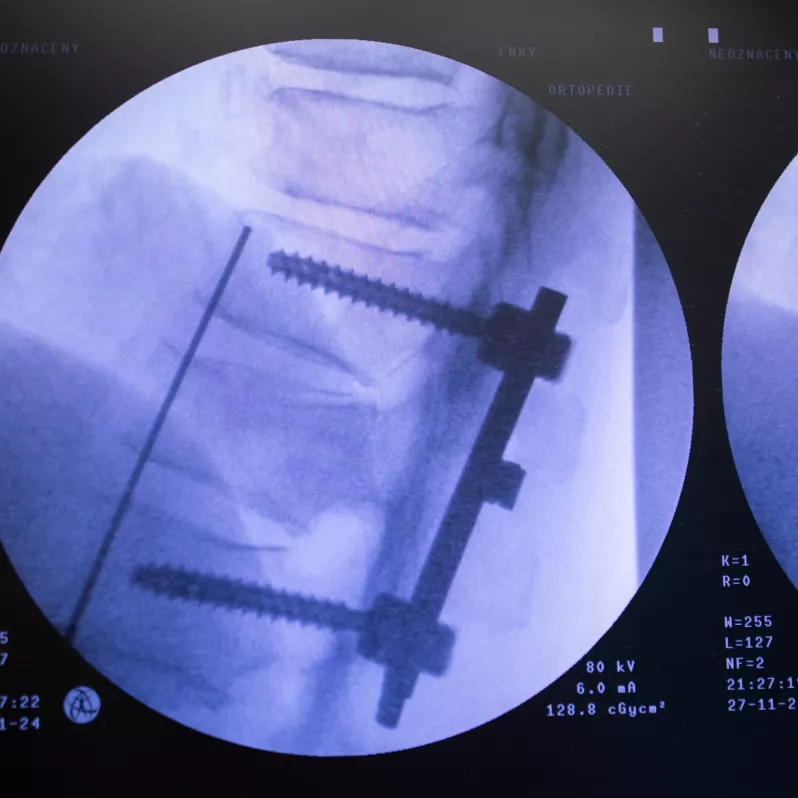

MOSS VRS®

A complex system for stabilization and immobilization of the non-cervical spine through a posterior approach, possibly as an adjunct to fusion. It is manufactured by the German company Biedermann Motech.

Who is it for?

Patients suffering from degenerative disc disease, spondylolisthesis, pain caused by trauma, spinal stenosis, tumour, pseudoarthrosis or in case of previous unsuccessful fusion can become implant recipients. When used in pediatric patients, the MOSS VRS® is also indicated as an adjunct to fusion in the treatment of adolescent idiopathic scoliosis. It is intended for use with autograft and/or allograft.

Why MOSS VRS®?

MOSS VRS® is a spinal system with a new generation of pedicle screw technology. This allows simple and repeatable polyaxial locking at any angle and at any time during surgery, even when using advanced corrective techniques. The Friction Fit® feature allows for temporary adjustment of the polyaxial screw heads for better rod insertion, further improving implant stabilization capabilities.

The rods themselves are made of a highly durable titanium-cobalt-chromium alloy. The system components are supplied in a range of anatomical sizes to meet the specific requirements and needs of as many patients as possible. The system is compatible with polyaxial heads MOSS 100®.

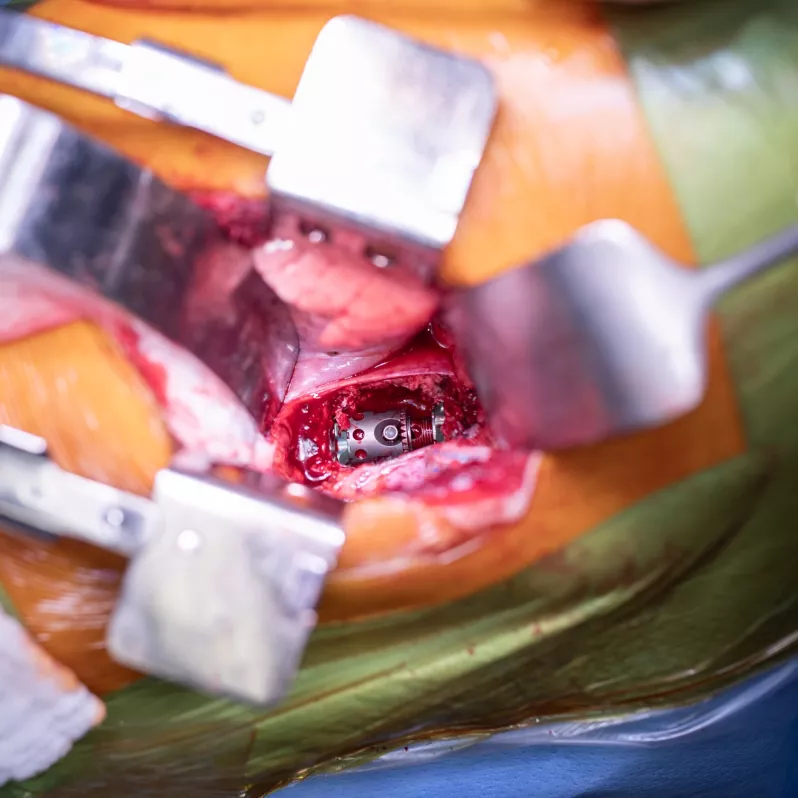

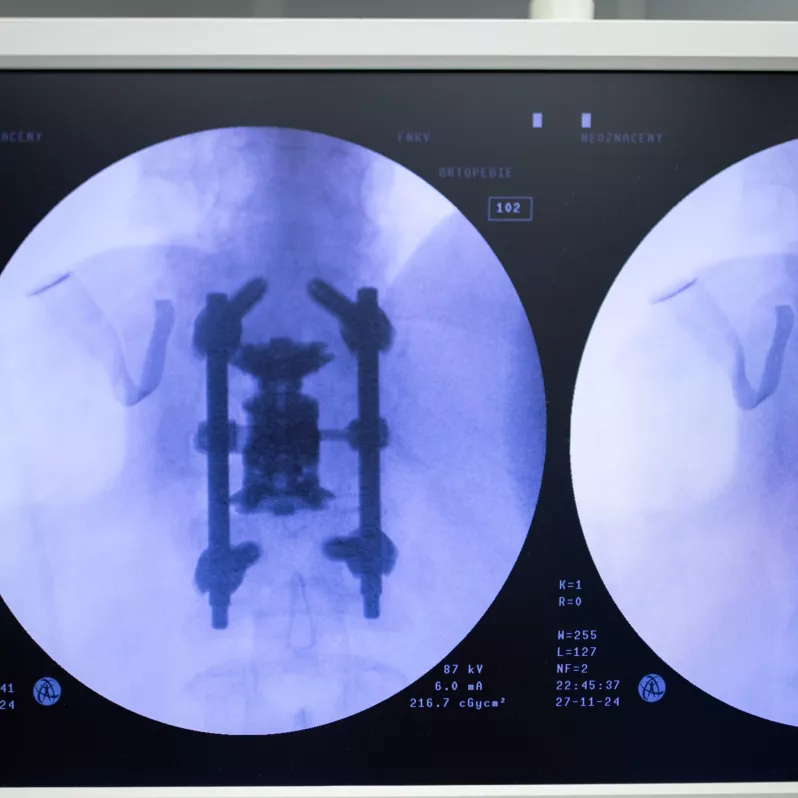

obelisc®

The vertebral body replacement obelisc® produced by German company ulrich medical is used for surgical reconstruction of substance defects of the anterior thoracic and lumbar spine.

Who is it for?

The implant is indicated for patients who have undergone a complete or incomplete corpectomy due to destruction of a vertebral body by e.g. tumor, fracture or inflammation. It allows to bridge the resulting defect up to a height of more than 130 mm, which in practice means replacing one or more spinal segments. The obelisc® implant is intended to be used in combination with another stabilisation system, such as the pedicle screw-rod system.

Why obelisc®?

Thanks to its innovative construction the vertebral body replacement allows for implantation of a minimally invasive nature and expansion directly in situ. The bevel gear drive in the loading device is designed to precisely adjust the required expansion, which can vary from approximately 20 to 130 mm depending on the nature of the procedure. The final fixation is carried out by means of a locking screw, which ensures high postoperative stability.

This stability is also contributed to by a variable system of end pieces, which easily adapt to the individual physical requirements of each patient. The serrations on these end pieces serve to anchor them even better to the vertebra cover plates. The implant itself is designed solely to capture axial compression forces.